Turnstile divider

Turnstile divider

Operating Behavior & Mechanical Characteristics

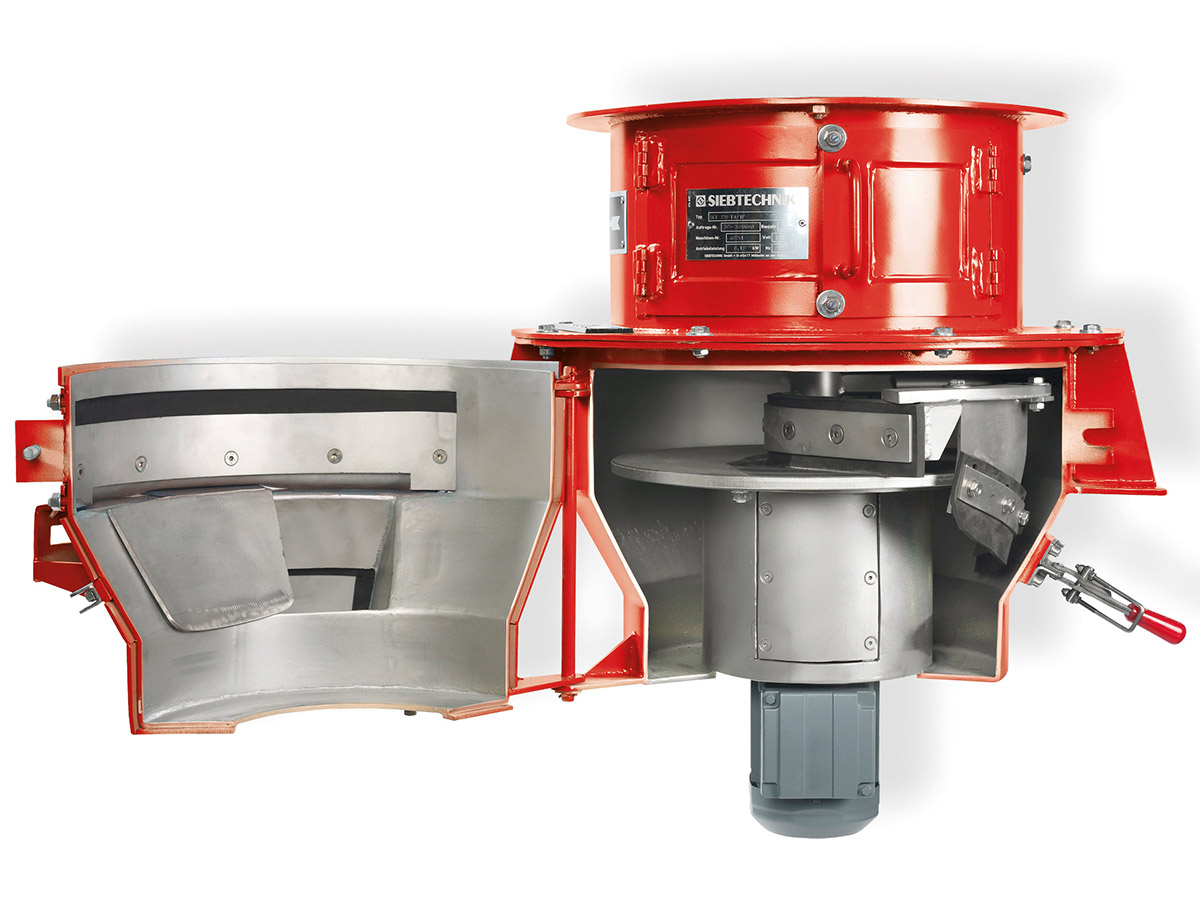

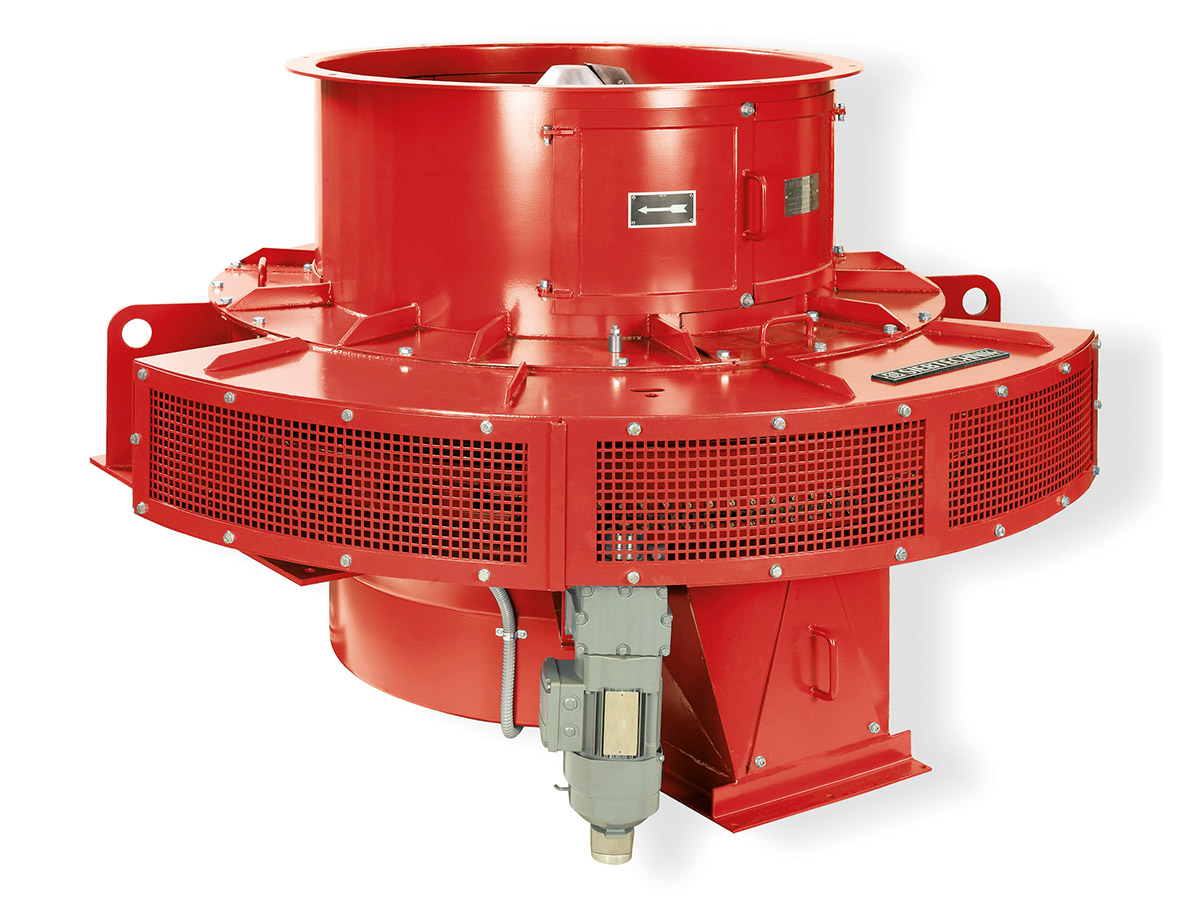

The turnstile divider is a divider that, with slight modifications, can be used for practically all products from cokes in lumps, plugged fine coal right up to super-fine-milled quick lime. The sampled material can be transferred to the divider’s charging area without prior dosing, since it is thoroughly mixed and dosed prior to the dividing stage proper by the inwardly-directed raking arm.

The material transferred to the middle of the divider plate via the first raking arm is now uniformly transported in a spiral movement outwardly over the edge of the plate by a second raking arm and drops onto a conically worked sheet housing, which is partly recessed. The product dropping onto this recess is designated the “sample”.

The material slipping to the middle of the plate via the cone is discharged as waste via the so-called gravity channel.

The turnstile divider offers the following advantages: This divider operates very reliably even with most and adhesive products through the forced guidance of the material stream through the raking arms and strippers. For divider regular cleaning, some types can be swung open by a third, increasing accessibility and minimizing cleaning time.

The dividing ratio can be varied by the recess in the conical section being closed by means of a side plate in the range of 1:4 up to 1:168 depending on the particular divider size concerned. Appointing two dividers consecutively enables dividing ratios far above 1: 1,000 to be realized.

Advantages

- Very reliable operation even with wet and sticky products

- Low-wear and low-maintenance design

- Designed for increased accessibility, so minimum cleaning time

- Variably adjustable dividing ratio

- By arranging two dividers one behind the other dividing ratios of well over 1:1000 can be achieved.

Downloads

Contact us

Error: Contact form not found.