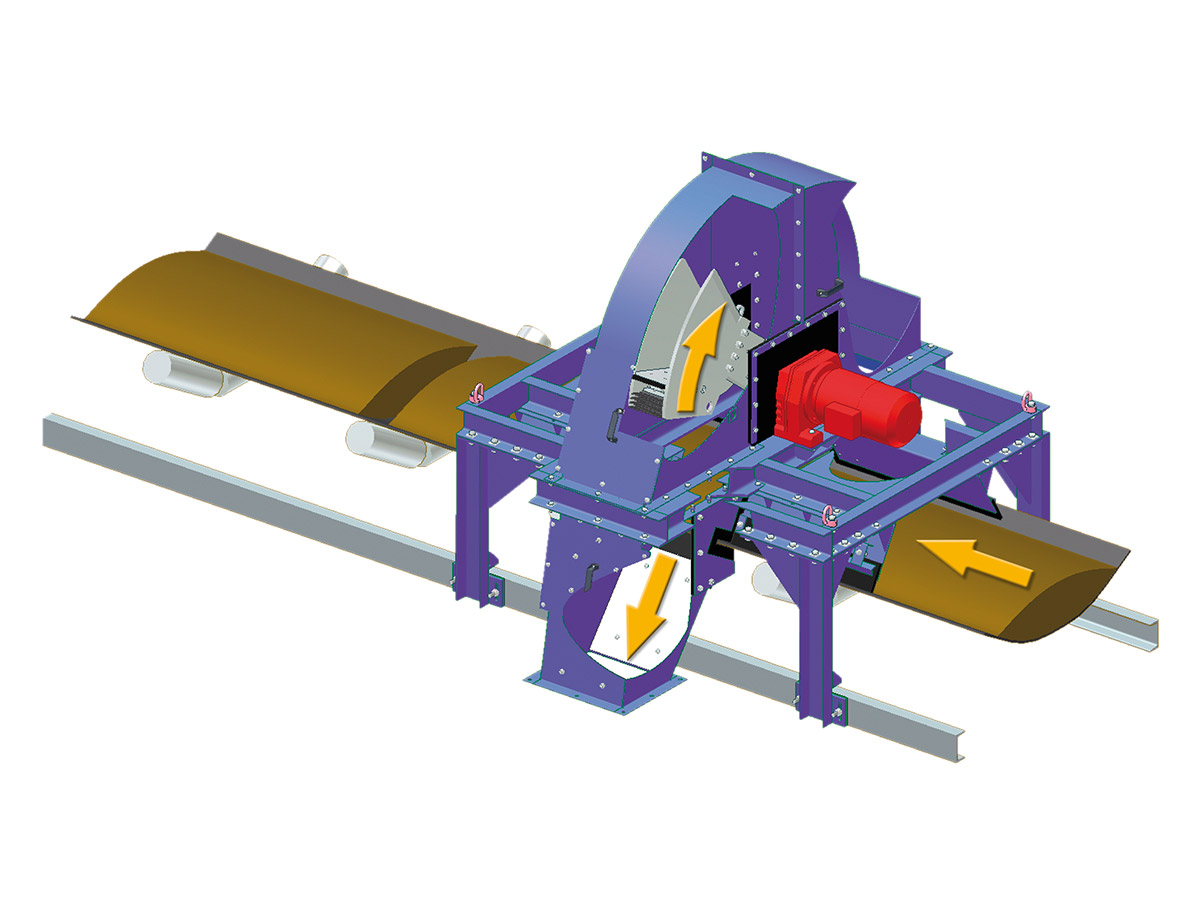

Hammer sampler

Operating Behavior & Mechanical Characteristics

The hammer sampler is implemented for sampling materials from belt conveyors. The hammer sampler guides this sampling frame, which is closed on one side, in a circular movement through the material stream as it moves along the belt. In doing so it automatically removes from the belt a representative cross-sectional sample corresponding to that of the sampling frame.

To ensure that the belt is not damaged and to obtain

a complete and representative sample, the shape of the sampler must be adapted to the various belt cross sections and belt depressions.

Also included here is the use of brushes and rubber wipers that ensure that fine portions adhering to the belt base are discharged into the sample and do not remain on the belt.

Advantages

- A simple, low-maintenance and very operationally reliable construction

- Reliable removal of the fine contents from the belt bottom by the integrated brush and scraper

- No conversion from 3-piece to 5-piece roller stand necessary

- Hardly any expenditure for changes to existing belt installations for retrofitting

- Reliable monitoring of the position of the sampling hammer

- Reliable stopping of the sampling hammer by means of the disk brake fitted to the geared motor

- Lower primary sample quantities compared with slotted-vessel samplers

- Available for all belt widths, speeds and conveyor performances usual in the market

Downloads

Contact us

Error: Contact form not found.