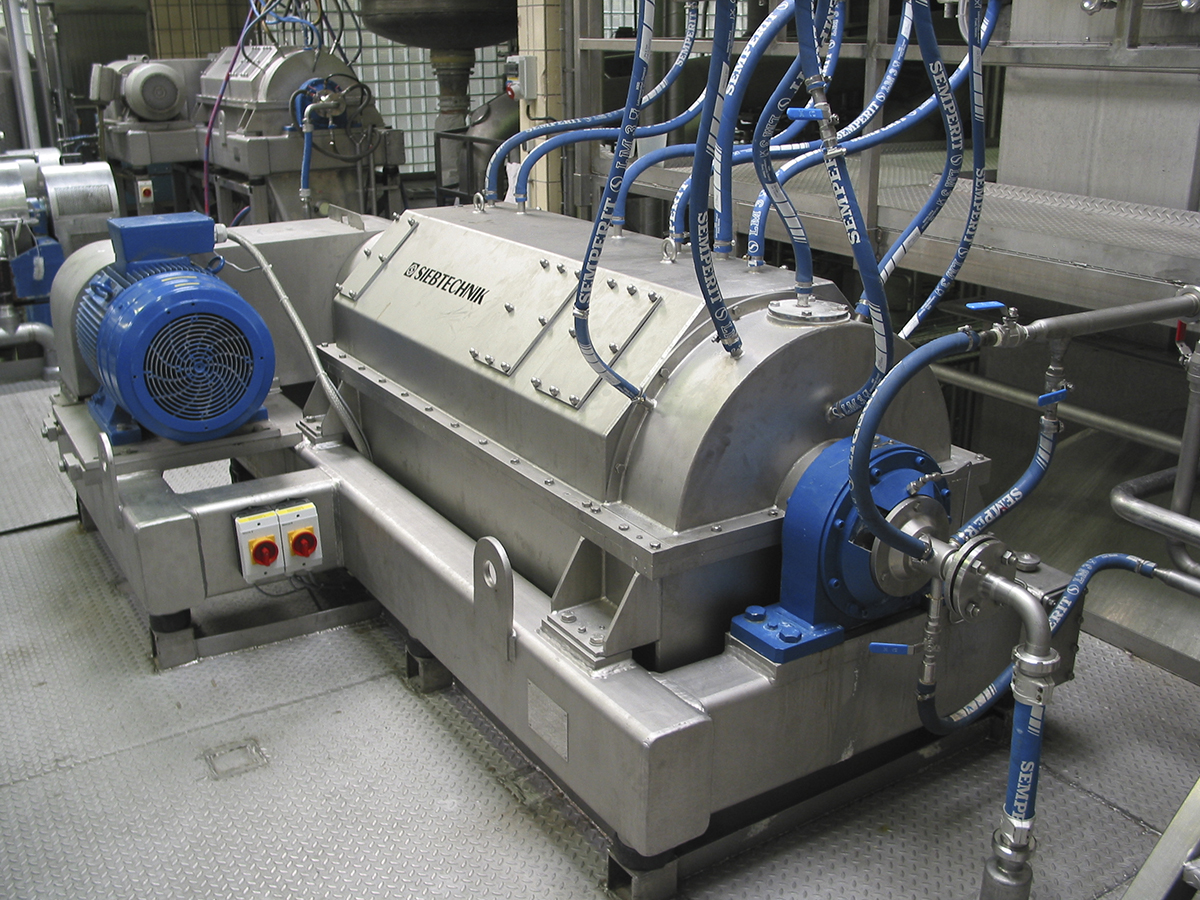

Decanter centrifuge

Decanter centrifuge

Individual, functional and versatile

The SIEBTECHNIK decanter centrifuge is a continuously operating solid-bowl worm centrifuge in tunnel or pedestal bearing design. Our decanters are individual, functional and versatile. They offer highly efficient separation of even the finest solid materials together with nearly complete clarification of the liquid phase.

The wish to further and further reduce the pollutant levels in waste water for the lasting protection of our environment (ZLD – zero liquid discharge) and demand by industry for production shops to be as efficient as possible make the decanter one of the most frequently used machines.

Whether it’s highest or the lowest throughputs, lowest or highest temperatures, gas-tight design, chemical resistance or explosion protection – we offer a solution.

Operational reliability under all operating conditions through, amongst other things, oil-circuit lubrication for all bearings, including gear unit and worm bearings has priority on SIEBTECHNIK decanter centrifuges.

Low maintenance costs as well as individual adaptation and design variants make our decanter centrifuges a unique separating apparatus for nearly all technical separating processes. These include pure separating processes (clarification and solids dewatering), thickening (compacting) and classification both in the open and gastight process.

Operational behaviour and mechanical characteristics

In decanter centrifuges very fine solids are separated from less dense liquid. The solid matter settles in the liquid, so is not retained by a screen element. The solid matter deposited in the solid bowl is conveyed by a worm to the small diameter and there discharged. The clarified solid matter drains away over an adjustable weir at the cylindrical bowl end.

SIEBTECHNIK decanter centrifuges operate on what is known as the counterflow principle. This means that the suspension to be separated is fed into roughly the middle of the drum, the settled solid matter is conveyed towards the small diameter by the worm rotating at a different speed from the bowl, while the clarified liquid runs over at the opposite end of the bowl.

The level of the liquid in the bowl and so the ratio of the clarification and the drying section of the bowl can be adjusted. This enables optimium adaptation to the separating task.

The difference in speed between worm and bowl is achieved by a high-performance gear unit. The unit is standardly driven by means of V-belts, the centrifuge being fitted with a single drive (fixed gear input shaft) or a dual drive (driven gear input shaft), depending on the speed combination.

Fitting variants

According to their design layout the TS series is preferably used for gas-tight process systems and the DZ series for open systems.

We build both machine variants with bowl tilts of between 6° and 15°, with a single or a dual drive, a hydraulic drive or with frequency inverter drive, as a two-phase decanter and with various centrate and/or solid discharge variants.

Technical specification

Application

Advantages

- Continous operation

- Wide range of applications in all areas of industry

- Flexible drive concept

- High machine availability

- Minimum maintenance

- Long service life

Downloads

Contact us

Error: Contact form not found.