Recycling & ZLD

Recycling & ZLD

Sustainable resource protection by recycling and ZLD

Since decades the worldwide scarcity of resources and raw materials has induced the sustainable reactivation of recyclable materials for reuse.

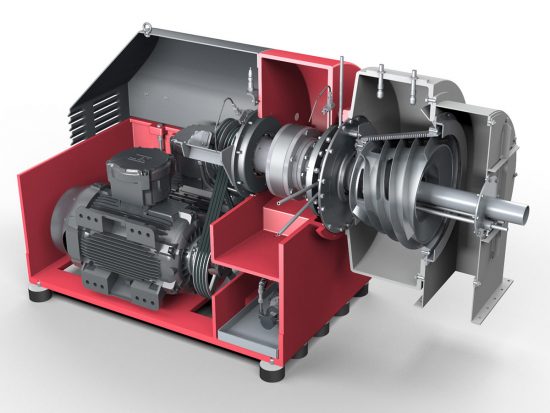

Our customers dewater e.g. X-ray films with the CONTURBEX Worm/Screen Centrifuge for reclamation of silver, for reclaiming plastics granulates from motor car recycling or also of HDPE from recycling of beverage packaging. We are developing in-house the necessary special slotted screens or CONIDUR® screens for dewatering.

The salt load of waste water, e.g. from power stations or from the potash industry, must be minimized. This can be achieved, amongst other methods, by means of Zero Liquid Discharge (ZLD) plants. In this application dewatering is effected by means of decanters, SHORTBOWL decanters, pusher centrifuges and CONTURBEX centrifuges. For dewatering of rough residues our vibratory centrifuges HSG have a proven record.

More fine mixed salts from cristallisation plants are centrifuged with downstream SHORTBOWL decanters, pushing centrifuges and CONTURBEX centrifuges at operating temperatures of partly over 100°C. The highly alloyed special steel types, Hastelloy and Titan materials required for these machines are coated for appropriate wear protection with tungsten carbide, Stellite or ceramic tiles. In this innovation-driven market we develop continuously for our customers new and still more efficient solutions for the coating, bonding and joining technology.

Titel