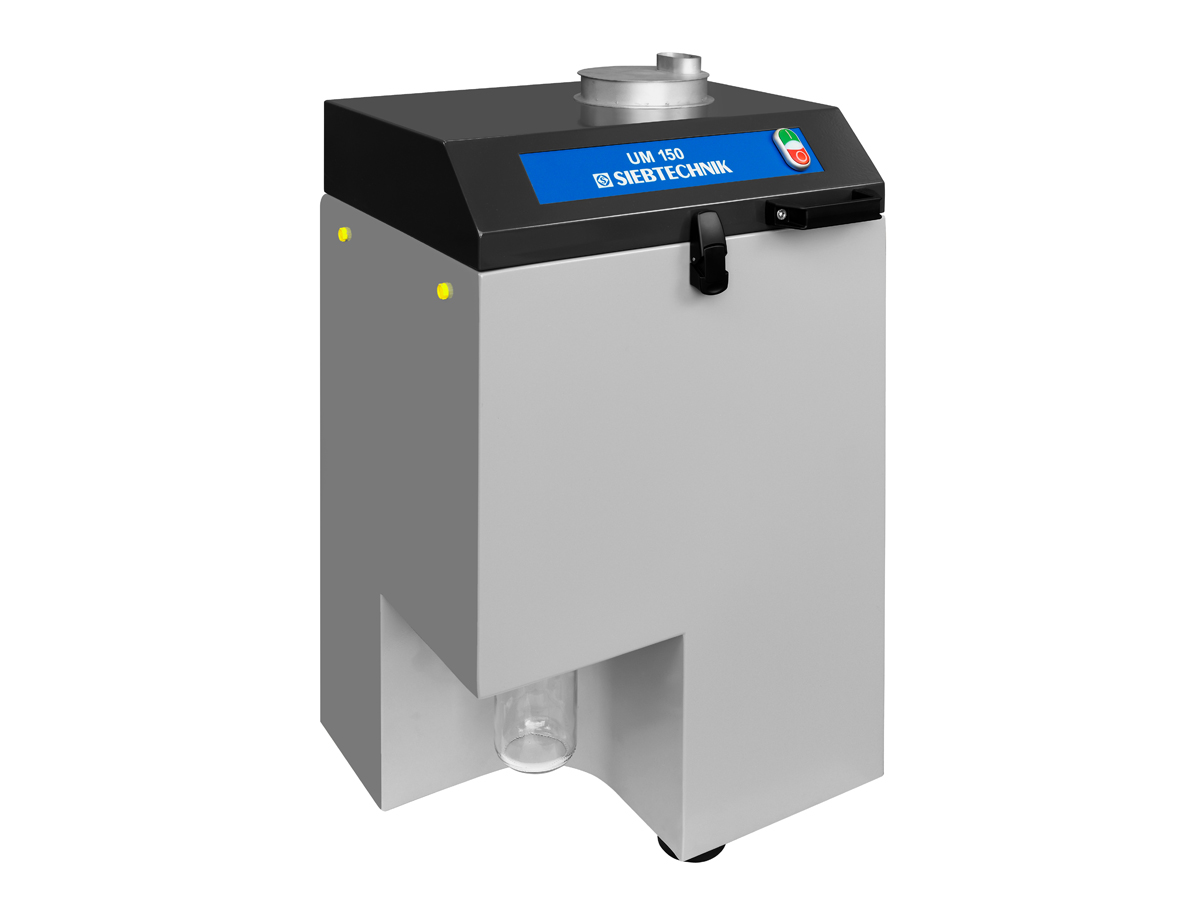

Multi-purpose mill

Multi-purpose mill

The multi-purpose mill UM 150 is used for finely grinding – up to a hardness of approx. 6 on the Mohs scale – dry, brittle, medium-hard materials < 15 mm fed in doses. The grinding effect is based on impact and shear force, caused between the rapidly turning rotor and toothed grinding path.

Operating Behavior & Mechanical Characteristics

The fed material is ground until it can pass the slotted screen insert with the exhaust air. This enables any overgrinding of already produced fine material to be eliminated. The ground material removed with the exhaust air is subsequently separated, through a cyclone, in a sample collecting bottle (500 cm³). Instead of the sample-collecting bottle, a pipe can be optionally screwed into the opening in the housing base, enabling a larger vessel to be installed underneath the machine.

To inspect and clean the machine, its housing cover can be opened, so that the grinding chamber and the cyclone can be fully examined. The damper-supported cover is monitored for the operator’s safety, and when it is opened causes an instantaneous emergency stop by the brake motor.

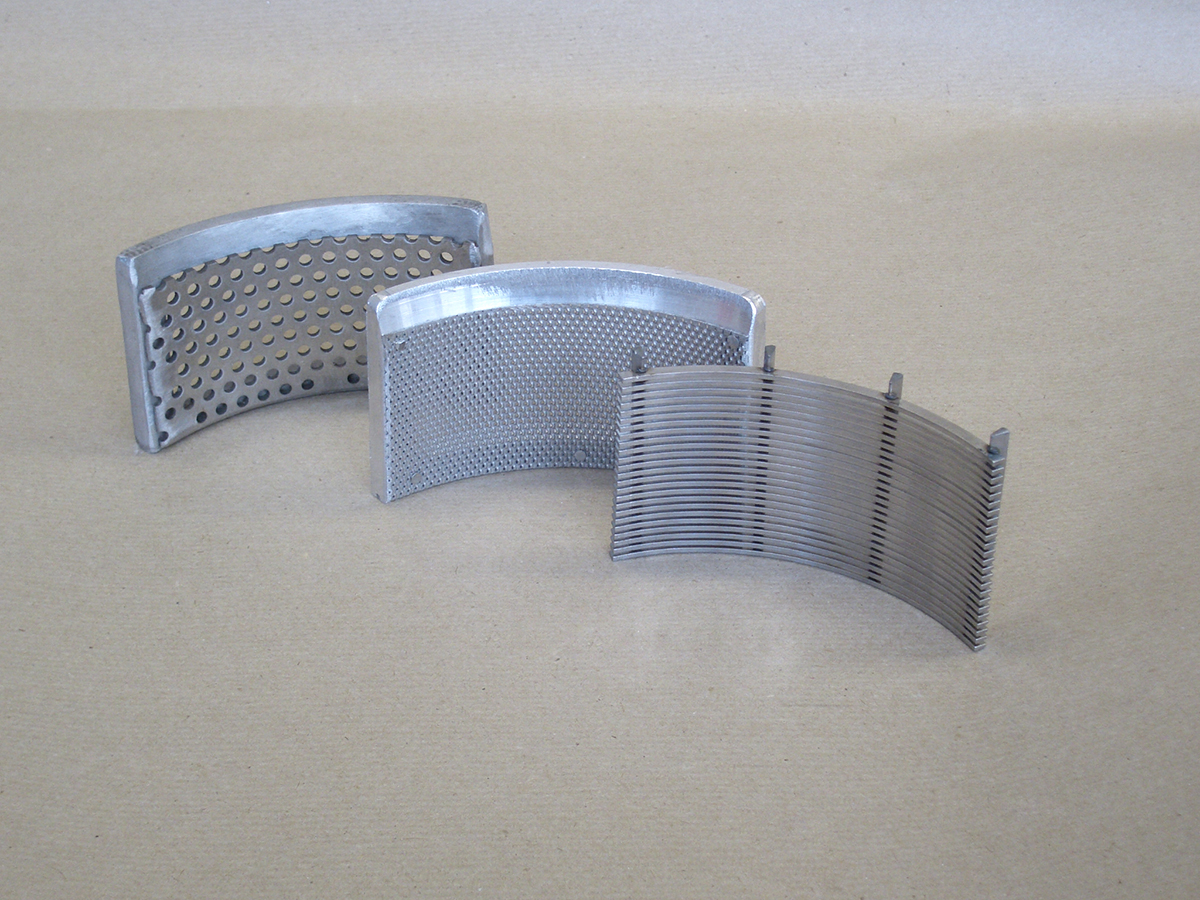

When the cover is opened, the slotted filter inserts, that are decisive for the fineness of the final product, can be slid into the appropriate section of the grinding path.

Technical specification

Advantages

- Low-wear and low-maintenance design

- Overgrinding of fine material is eliminated

- Grinding chamber and cyclone can be completely viewed for inspection and cleaning

Downloads

Contact us

Error: Contact form not found.