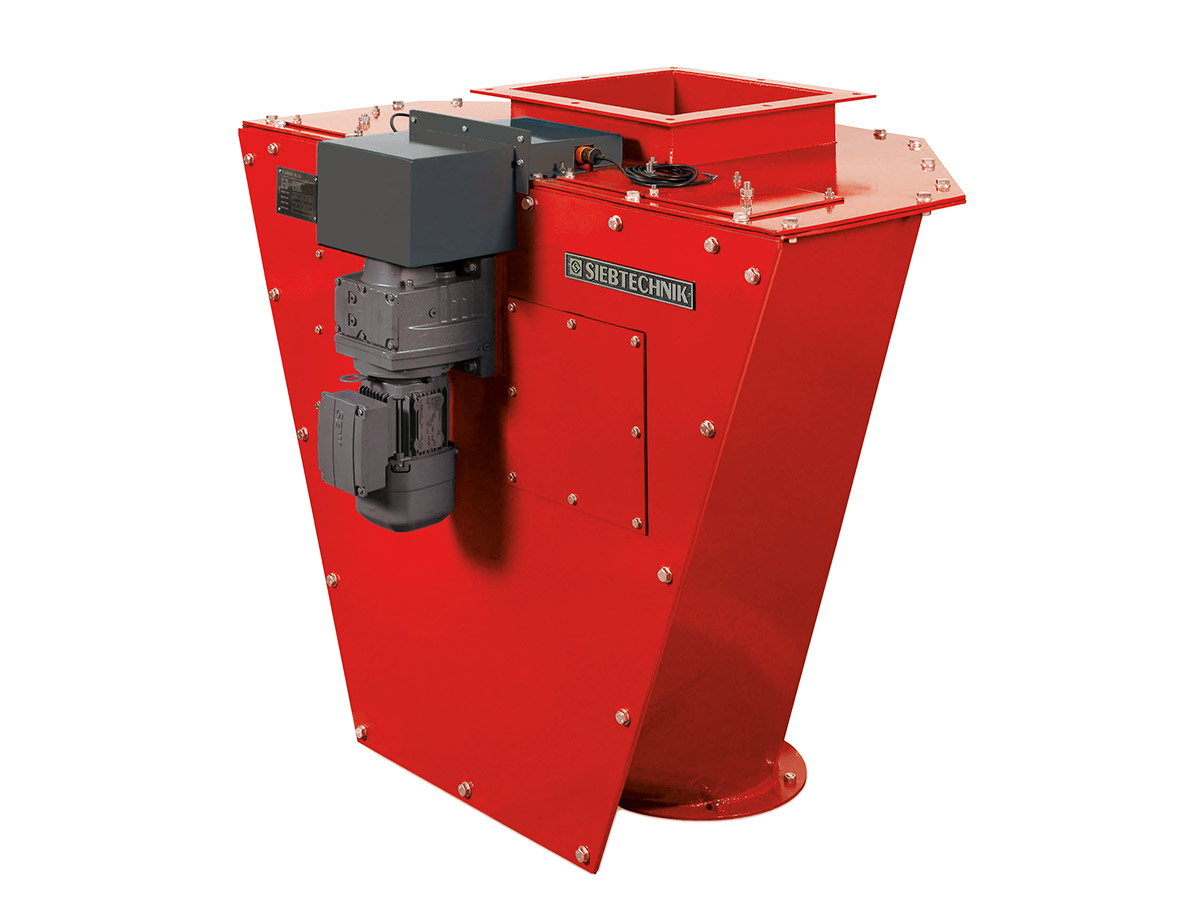

Downpipe/ slurry sampler, Type FPN/TPN

Downpipe/ slurry sampler, Type FPN/TPN

Operating Behavior & Mechanical Characteristics

Representative sampling is carried out by a sample chute that is guided in a circular movement through the material flow at a constant speed. While the sample chute is rotated through the material flow, a partial material flow is continuously separated and led off. The thus obtained sample material is collected via a pipe socket and further processed. While the waiting position of the sample chute between two samplings is inside the material space, it is, however, outside the principle product flow, so that direct contact between the sample chute and material flow is prevented and wear on the sample chute reduced.

The sample chute can be powered both by a geared motor as well as via a pneumatic cylinder.

The distinction between downpipe and slurry sampler refers to the material flow to be sampled and has an influence on the discharge angle of the sample chute.

Technical specification

| Downpipe/ slurry sampler | FPN / TPN | |

|---|---|---|

| Nominal diameter of the downpipe | mm | 200 - 800 |

| Installation height | mm | 500 - 3000 |

| Weight | kg | 80 - 3000 |

Advantages

- Representative sampling from product flow

- Low-wear and low-maintenance design

- Also available as slurry sampler for suspensions

Downloads

Contact us

Error: Contact form not found.